In addition to providing cooling tower parts, our wide range of capabilities include basic technical assistance and field service support as well as installation, commissioning and start up, performance testing and optimization, including recommendations for upgrades, energy savings and wet-dry conversions.

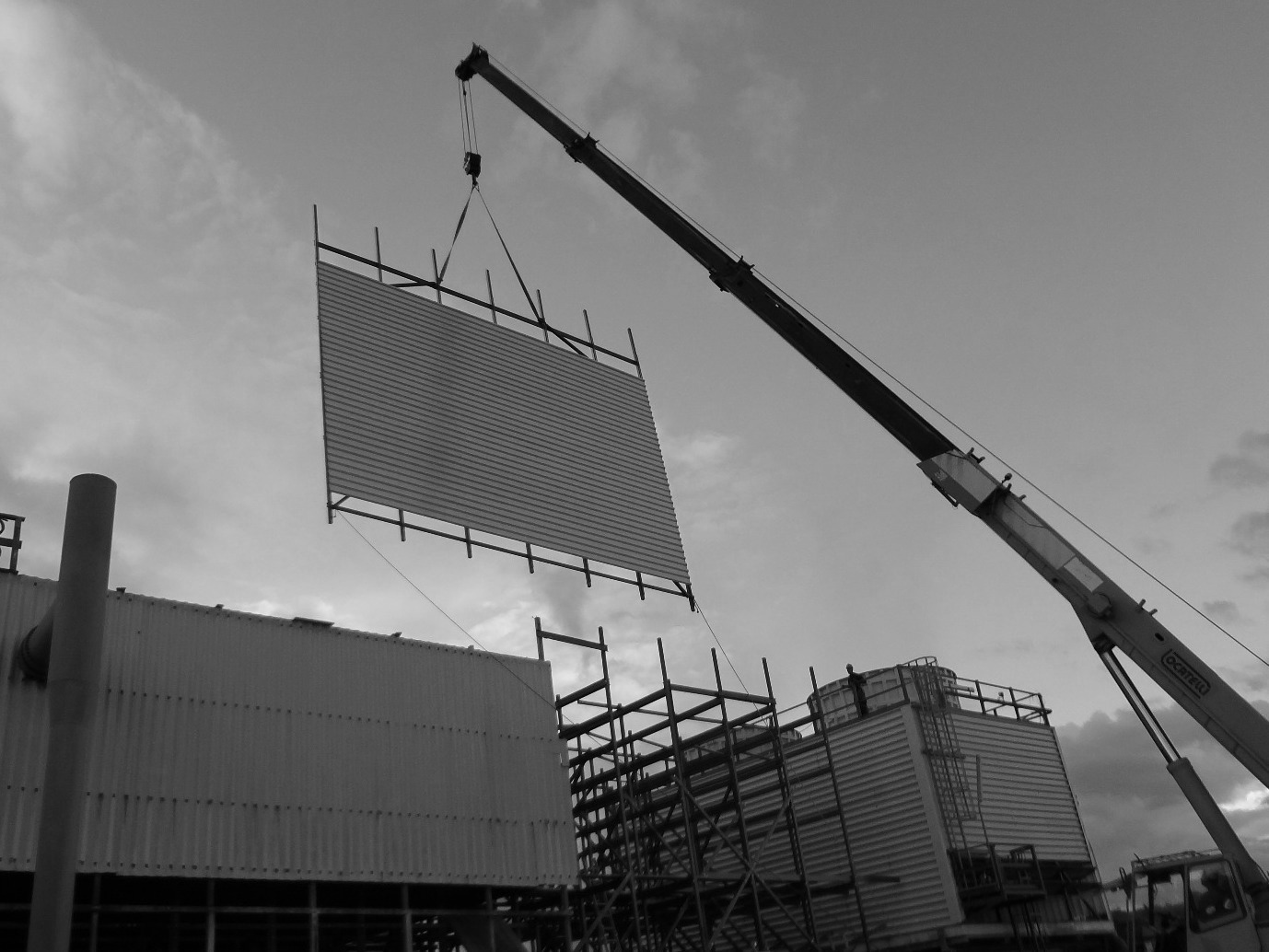

A dedicated, multi-disciplined after-sales team is committed to executing projects successfully and in compliance with various international engineering standards. We have successfully completed many equipment upgrade projects while the plant is operating, reducing or eliminating downtime.

- Wet, dry and hybrid cooling system solutions

- Wet-to-dry system conversions

- Maintenance, overhaul and upgrades

- Cooling tower parts, components and field service

- Cooling system inspections

- Online monitoring

- R&D testing

- Operational and maintenance training

Wet and Hybrid Service Activities

- Complete replacement tower; on existing basins

- Fill replacement

- Drift eliminator replacement

- FRP/PVC distribution replacement and reconstruction

- Hot water basin replacements

- Structural reconstruction

- Fan deck replacement

- Mechanical replacement of fans, gears, drivers

- Shafts and Motors

- Hot water deck access ladders and plenum

- Walkways

- Casing and louvers: FRP, plywood, PVC, cellular

- Stairways and ladders

- Fill and drift access, platforms

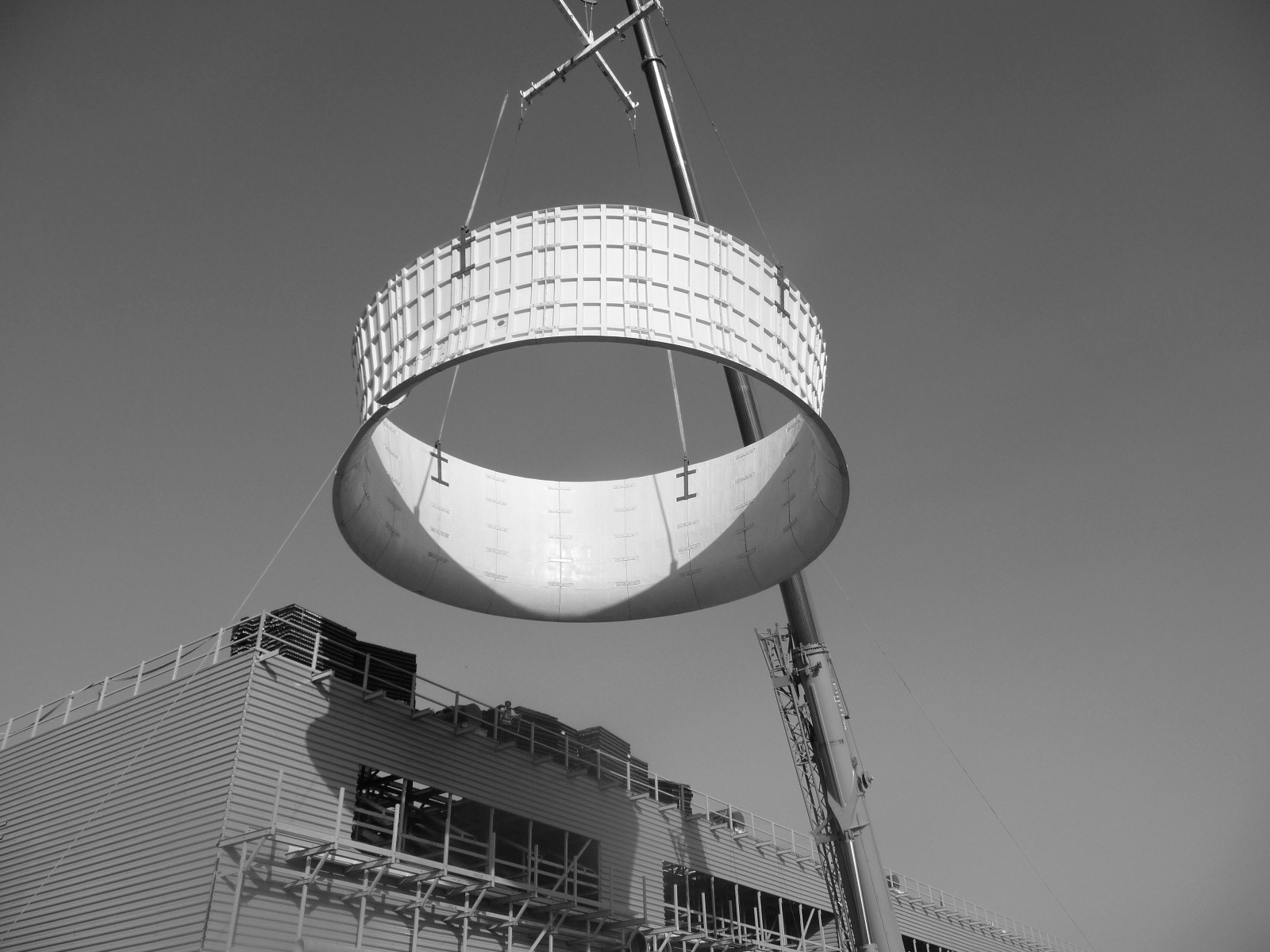

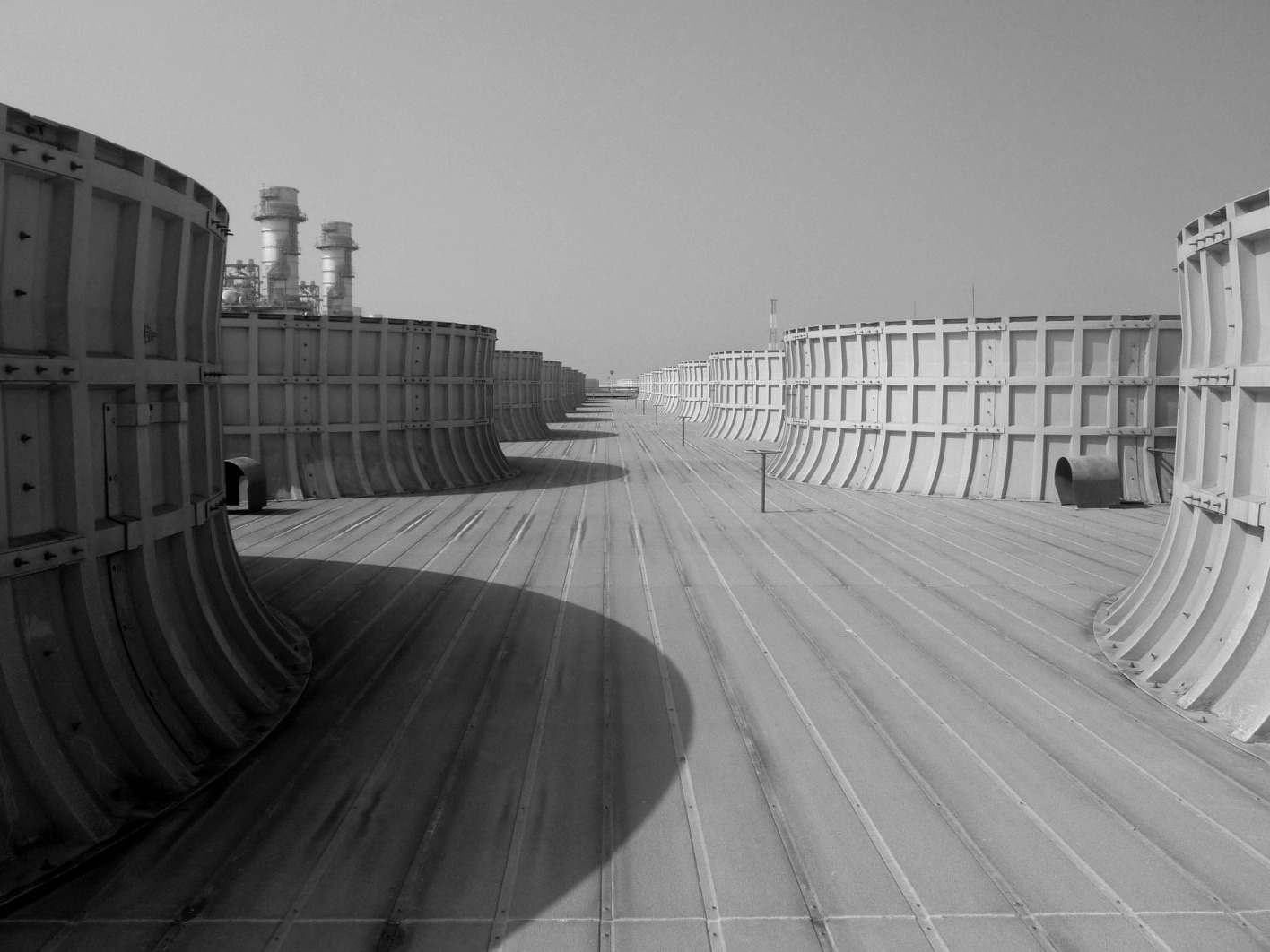

- FRP fan stack replacements

- Complete tower or individual cell refurbishment

- Crossflow to counterflow conversions

- Full Wet CT to Hybrid CT conversions (Hybridization)

- Concrete tower internals and reconstruction

- Roof top replacement & repairs

- Fire and lightening protection.

SPIG activities at site

Dry Service Activities

- Retubing

- Finned tube renovation

- Tube bundle supply and renovation

- Complete ACC upgrades

- Heat exchanger section expansion

- Mechanical improvements: fans, stacks, ducts

- Structural components and auxiliary systems.

Cooling tower inspections include:

- Capabilities for wet, dry, hybrid and specialty cooling systems regardless of OEM

- Thermal performance assessment

- Structural integrity evaluation

- Remaining life assessment

- Full reports with custom maintenance plans